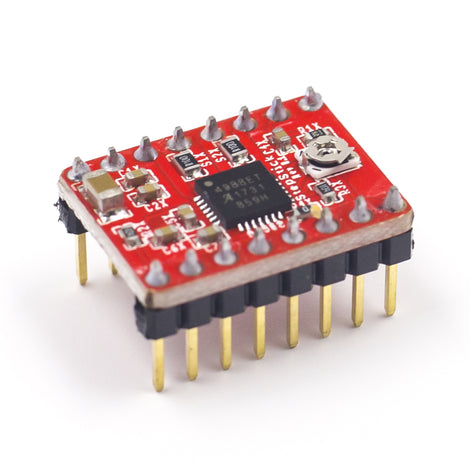

DRV8825 Stepper Motor Driver with Heatsink

- $1.50

- Brand: Kuongshun Electronic

- Availability: In Stock

- SKU: 3A006

3D Printer Stepstick Drv8825 Stepper Motor Driver Reprap with Heatsink Product Introduction: The DRV8825 stepper motor driver carrier board TI DRV8825...

Tags: 3D Printer Board

3D Printer Stepstick Drv8825 Stepper Motor Driver Reprap with Heatsink

Product Introduction:

The DRV8825 stepper motor driver carrier board TI DRV8825 micro bipolar stepper motor drive is a breakthrough. The module has a pinout and interface with our A4988 stepper motor driver carrier is almost the same, so it can be used as a better performance of the pull-down menu board replacement in many applications. DRV8825 features an adjustable current limit, overcurrent and overtemperature protection, six micro-resolution (down 1/32-step). It uses 8.2 - 45 V, can provide up to about 1.5 per phase no heat sink or forced air flow (rated up to 2.2 per volume sufficient additional cooling).

- A simple steps and direction control interface.

- Six different steps resolutions: full step, half step, 1/4-step1/8-step1/16-step, 1/32-step.

- Can interface directly with 3.3 V and 5 V systems.

- Over-temperature thermal shutdown, overcurrent shutdown, undervoltage lockout.

- Short to ground short circuit load protection.

- 4 Layer 2 oz copper PCB, in order to improve heat dissipation.

- Exposed solder ground below the bottom of the driver IC on the printed circuit board pad.

- Module size, pin and interface matching A4988 stepper motor driver operators in many ways.

- Adjustable current control lets you set a potentiometer, which lets you use the stepper motor's rated voltage or more, in order to achieve a higher rate of maximum output current step.

- Intelligent chopping control automatically selects the correct current decay mode (fast decay or slow decay).

- Maximum 45 V supply voltage.

- built-in voltage regulator (the need for any external logic supply voltage).

Parameter:

- Size: 1.5mmX2mm (same as 4988)

- Drive current: 2.5A

- Subdivision: 1,1 / 2,1 / 4,1 / 8,1 / 16,1 / 32

- Manufacturing process: SMT placement machine manufacturing, non-manual welding, higher yield, more stable performance.

Suitable for:

- Need to drive stepper motor occasions.

- Is to build 3d printer, cnc, engraving machine and other essential modules.

- Supported 3d printers are Prusa Mendel, ultimaker, printbot, makerbot and so on.